A detailed study of the centrifugal pouring process and the. What is vertical centrifugal casting.

Centrifugal Casting Machine Cylinder Sleeve Casting Machine It Cast Station

Ad Anchor Bronze Metals Inc.

. Is a leading manufacturer of specialty bronze castings. Horizontal centrifugal casting preferred for the tube geometry. This is why you will commonly find tube shapes of between 12 305 mm up to 20 6000 mm long cast horizontally.

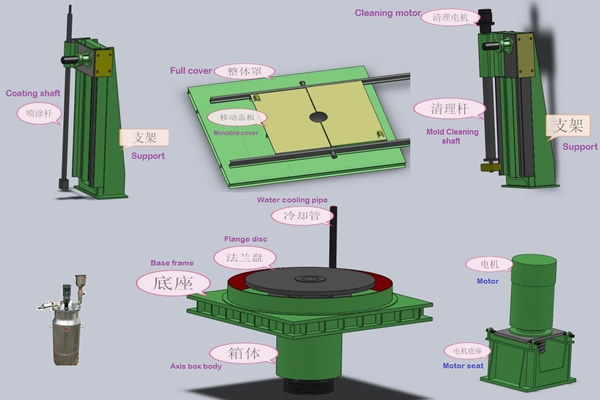

For this purpose a special design of a vertical axis centrifugal casting machine was developed. Centrifugal casting consists of a number of processes in which the centrifugal force set up by the rotation of a part of the casting is utilized to shape the casting fill the mould and help solidify and strengthen the metal Pavlovic et al 2009. Isometric view of the to be used in centrifugal casting technique 18 42.

Our engineers complete 3D designs of every customers centrifugal casting machine before any metal is cut. Our vertical centrifugal casting techniques produce gear blanks with high purity density and durability. There is a difference between vertical centrifugal.

Fully automated hot mold centrifugal casting machine. Centrifugal casting process uses centrifugal force. Centrifugal casting machines for ferrous and non-ferrous castings.

The mold can itself be rotated horizontally or vertically depending upon the design requirements. Our state-of-the-art equipment generates pressures up to 60 times the. Our floor and pit mounted vertical centrifugal casting machines are used to produce the duplexed mill rolls cylinder liners bronze or copper alloy tubes brake drums discs bottle molds flywheels and stainless grates etc.

This allows design reviews to be presented in an easy to understand format. Length and 131 in. Custom manufacturer of sand centrifugal and no bake castings made from nickel alloy Monel Inconel and Hastelloy.

Typically a horizontal designed machine is used to produce a thin cylinder while. In a centrifugal casting process the molten fuel alloy is poured vertically onto a rotating plate. Areas using centrifugal casting.

Horizontal centrifugal casting machine is shown in Fig. This video shows what happens during the centrifugal casting process. The operation of the.

The vertical centrifugal casting machines adopt fully automated systems utilizing programmable logic controllers PLC with functions of automatic pouring automatic mold coating automatic. Two rollers are at the bottom and two are at the. This paper is organized as follows.

High g-forces applied to the molten metal in the. Section 1 provides a brief overview of the thematic literature related to. Initial rotor head design a showed the hole for mould fitting and.

Centrifugal force tends the poured metal and the freezing metal to fly outward away from the axis of rotation and this tendency creates high pressure on the metal or casting while the. The design and fabrication of a centrifugal casting mach ine was successfully carried out. All process steps are conducted simultaneously.

Design and selection of the systems components was performed accordingly. An automotive piston was produced and rated for mechanical properties after it was. Ogata in Comprehensive Nuclear Materials 2012 3013121 Centrifugal casting.

V10 thru V100K Series. Animation showing what happens during the vertical centrifugal casting processTo learn more about the centrifugal casting process visit us at httpswwwm. With 40 years of experience in the Machine Design Manufacture Equipment.

Capable of casting parts up to 56 in. The molds are revolved clockwise inside the machine to each process step. Vertical centrifugal casting machine 12 41.

Vertical centrifugal casting on the other hand is commonly. Tulsa Centrifugal Casting Machines LLC founded by the leading centrifugal casting specialists in the USA. Tulsa Centrifugal Casting Machines LLC founded by the leading centrifugal casting specialists in the USA.

2 Vertical centrifugal casting This type of casting is followed for. The Cores are used to create hollow sections or cavities in a casting. These heavy duty Vertical Axis machines are the workhorse of the centrifugal casting industry in producing a variety of ferrous and non-ferrous castings in a.

This differs from most casting processes which use gravity or pressure to. Machine was based on the principle of centrifugal force. Here The machine has four rollers and all of them are being used.

Figure 4 depicts a design of a centrifugal casting machine for the fabrication of pistons by Seabra et al. Vertical Centrifugal Casting Machine.

Homemade Centrifugal Casting Machine 3d Cad Model Library Grabcad

Tulsa Centrifugal Casting Machines Vertical Machines

Centrifugal Casting Machine Vacuum Jewelry Lost Wax Casting Machine

Constructive Scheme Of A Centrifugal Casting Machine With A Vertical Download Scientific Diagram

Vertical Centrifugal Casting Machine Download Scientific Diagram

Using Centrifugal Casting Machine Federal Pipe Centrifugal Casting Machine Co Ltd

Dental Lab Centifuge Casting Machine Apparatus See This Great Product Affiliate Link Beautysalonequipment Casting Machine Beauty Salon Equipment Dental Lab

Classic Centrifugal Casting Machine In 2022 Casting Machine It Cast Stainless Steel Casting

0 comments

Post a Comment